Our Process for Painting Cabinet Doors

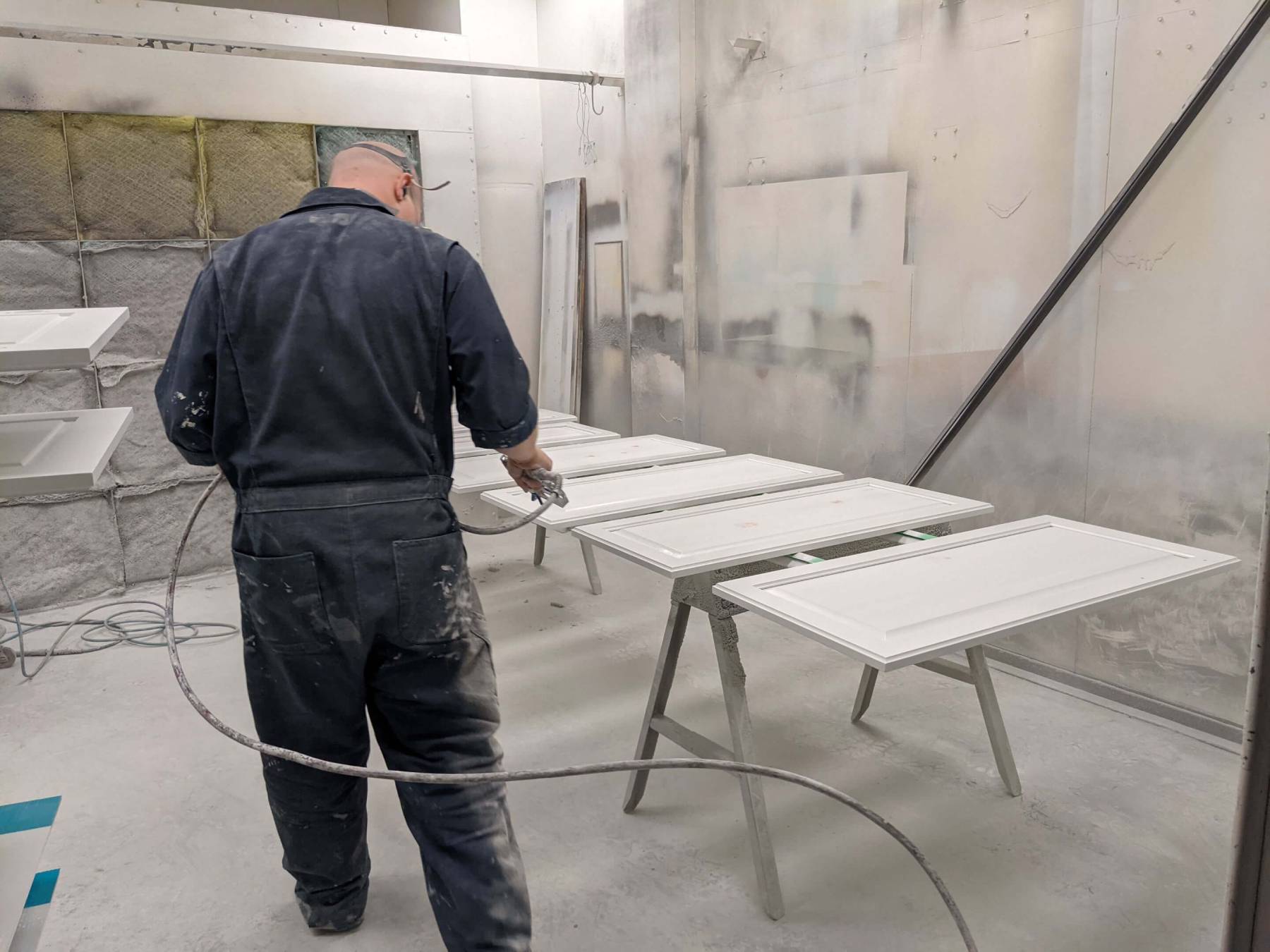

One of the key steps in our process of painting cabinet doors is removing all the cabinet doors, drawer fronts, shelves, man doors (if applicable) and any other piece that is easily removed and transported. When they return to a client’s home, they are completely renewed, with a brand new surface coating. Many of our clients love to know what goes on at our professional spray booth, how their doors are treated and what process they go through. So much so that some even chose to visit us at the shop while their doors are being done.

The process that doors, drawer fronts and other pieces brought into our spray booth go through is meticulous, standardized, and quality-controlled to ensure each piece looks virtually brand new. In this article, we will outline that very process and give our readers a better understanding of what each step means, why it is important, and how it all results in a cabinet door that not only looks brand new but is sporting a modern and chic colour that looks factory-made.

Intake – Your Cabinet Doors Arrive at the Paint Booth for Painting

The first step for the painting cabinets doors after we have started a kitchen cabinet painting project is to uninstall them from the cabinets inside the home and have them delivered to our spray booth. Upon arrival, each set is labeled by client or project name, counted to assess total number of pieces, organized onto a rack and assigned the colours that will be used. From there, the project is scheduled out based on each step and the process can begin.

Cleaning and Degreasing, Cleaning Cabinet Doors Prior to Painting

First things first, each piece is thoroughly washed with either a TSP degreasing mixture or a general grease-fighting cleaning solution. After rinsing and drying, the pieces are organized by size and placed back onto the rack. This initial cleaning step is critical to ensure that each piece being sprayed will not have any residue, grease, or substance that may react with the lacquer solvent and cause bubbling or poor adhesion.

Repairing Cabinet Doors, Filling the Large Scratches & Dents

The process for painting cabinet doors wouldn’t be complete with out repairs. Once every piece is washed and dried, the repair process can begin. If the doors are already painted, we have to start by removing as much of the original paint as possible, either by power sanding or chemical stripping agents. Those processes are worthy of an article on their own, but to keep this brief, assume the pieces are sanded smooth. Each piece is put under lighting to reveal the largest and most prominent imperfections, gaps, holes or seams that require a heavy duty wood filler. Once the most prominent imperfections are filled, the set is put aside to dry.

The First Sand & Prime

Once the wood filler is properly dried on the whole set, each piece is sanded with 220 grit sanding pads on an electric palm sander connected to a vacuum for dust control. Any detailed areas or profile spots that the power sander does not reach is sanded using the same grit on a hand sanding sponge or sand paper. Once each door is thoroughly sanded and all wood filler patches are flush with the door surface, each piece is dusted off, organized onto the racks and sent to the line for initial priming. Each piece is sprayed with our high quality primer, back side first (if applicable) for the entire set, allowed to dry, then flipped and primed on the front.

Fine Detail Repairs

The first stage of priming, mostly due to it’s flat off-white colour, helps reveal a great deal of minor imperfections, small surface scratches and dents, and any other small patchwork that does not get filled during the wood filler phase. The next step in our process for painting cabinet doors is that fine detail spots are filled with glazing and spot putty, a red Bondo-like substance that adheres to smaller imperfections much better than wood fillers. Once dried, this putty sands down to give an exceptionally smooth feel and total adherence to the surface material.

The Second Sand & Prime

Once the glazing putty has set, each piece is power and hand sanded thoroughly once again, this time using 320 grit to scuff and polish the primer layer and level out the putty spots. Once fully sanded and dusted, the entire set is once again sent in for a full coat of primer. This helps to ensure the red mud spots are properly primed as well as providing two solid layers of primer to give a stable base coat for the top coats of colour to adhere to. Once the entire set has received the second full coat of primer, they are set aside to fully dry prior to receiving the final sanding and topcoat.

The Final Sand and Top Coat

When a set of cabinet doors is ready for colour, we once again sand every piece with 320 grit sand paper, this time mostly by hand as the primer simply needs a scuff and polish to achieve that smooth and synthetic feel. The set is once again dusted off and sent in to the booth for spraying. The top coats of coloured lacquer are sprayed with a bit more attention to detail and full coverage, but otherwise it is the same process as spraying primer. The back sides are fully coated with two layers of colour, left to dry long enough and then flipped and finished with the front sides up. This process ensures both sides of a door or drawer front receives two coats of colour, while the side profile is passed with the sprayer a total of four times.

Air Drying & Wrapping for Delivery Once the Cabinet Door Painting is Complete

Every set is either hung to dry using clips and hangers, or placed flat backside down on a rack to air dry. It is recommended in our shop that a minimum of twenty four hours passes between finishing a set and having it ready to be wrapped and delivered, to allow an initial cure and hardening of the surface lacquer. At the end of this entire process, what we are left with is a cabinet piece that looks virtually brand new, with a renewed surface finish and a brand new colour and sheen.

When all is said and done, the doors are organized by size, wrapped and stacked using foam or quilted padding and plastic wrapped. Then they are shipped out for delivery and reinstall with our installation team.

You May Also Like:

Our Process for Painting Kitchens and Bathrooms

Best Surfaces For Sprayed Lacquer

Stained Vs. Painted Cabinets

Pros and Cons of Sprayed Lacquer

Durability of Painted Cabinets

The Importance of a Spray Booth